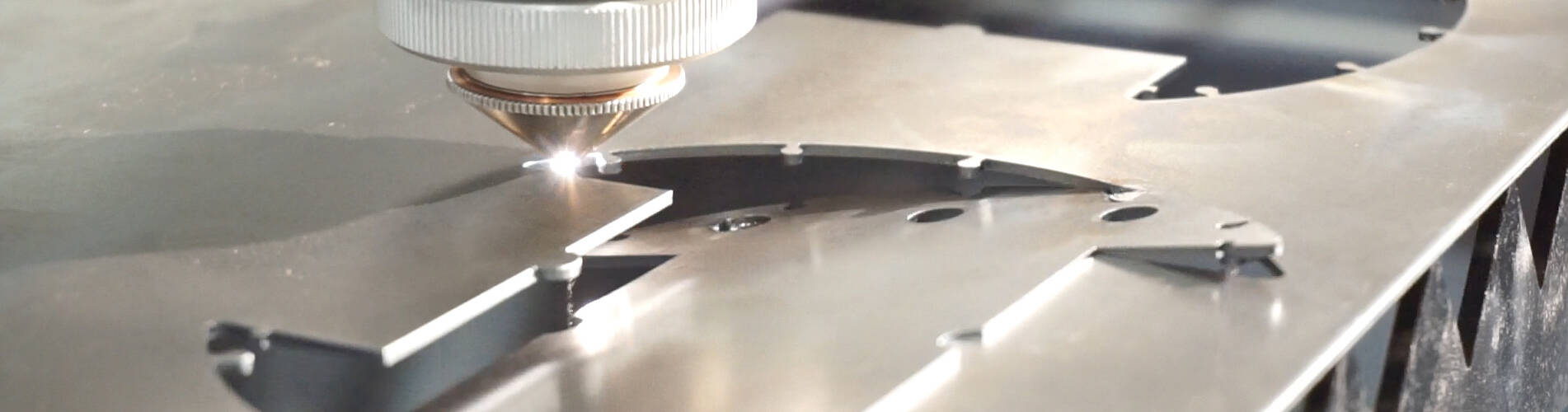

There are many ways to cut metal with cutting machines. In addition to the commonly known shears, slitting machines, water jets, etc., there are also thermal cutting equipment such as plasma cutting machines and laser cutting machines. There is also a

metal laser cutting machine, which is a laser cutting equipment dedicated to metal material processing. It can process carbon steel plates, stainless steel plates, galvanized plates, electrolytic plates, aluminum alloys, brass, and copper.

Today, we will introduce some advantages of metal laser cutting machine cutting common materials. Metal laser cutting machines generally use numerical control systems, which can cut and depict complex patterns on thin plates with very good accuracy, and can also cut on thick metal plates, and are widely used in the field of sheet metal processing. Stainless steel can be cut. Stainless steel has a wide range of applications, such as kitchen equipment, refrigerators, electrical appliances, washing machines, building materials, elevators, etc.,where you can see stainless steel.

Stainless steel cutting by a metal laser cutting machine, its cost is lower than that of traditional

wire cutting, and the speed is twice that of wire cutting. It can realize mass production and is a fast and effective cutting method.

For cutting carbon steel, laser cutting machines are widely used for carbon steel cutting. The advantage of carbon steel laser cutting machines is that they can cut arbitrary design patterns on the plate, with fast speed and high precision, and no need to deal with subsequent operations. In addition, the laser cutting machine does not need a mold to cut carbon steel, which saves costs and can also discharge materials, closely fit and save materials.

For cutting non-ferrous metals, laser cutting machines can also be used to cut non-ferrous metals, copper and brass. Both materials have high reflectivity and very good thermal conductivity. Brass with a thickness of less than one millimeter can be processed by nitrogen laser cutting; copper with a thickness of less than two millimeters can be cut, and the laser cutting processing gas must use oxygen.