Blog

What is electroplating? The process of electroplating, which in simple terms involves using an electrical charge to attach a thin metal layer or coating to an electrically conductive surface. Electroplating works like a galvanic cell in reverse. An electrical current reduces cations from a solution so that they can coat a conductive material with a thin layer. Benefits of electroplating Electropla...

What is sandblasting? Blasting is essentially like a pressure washer that uses “abrasive media” to create the desired look. The abrasive material we use includes sand, garnet, walnut shells, glass beads, and high-pressure water. We will pick the media, the pressure, the distance from the part after taking the desired surface texture, the material of the part, and the dimensional tolerances of the ...

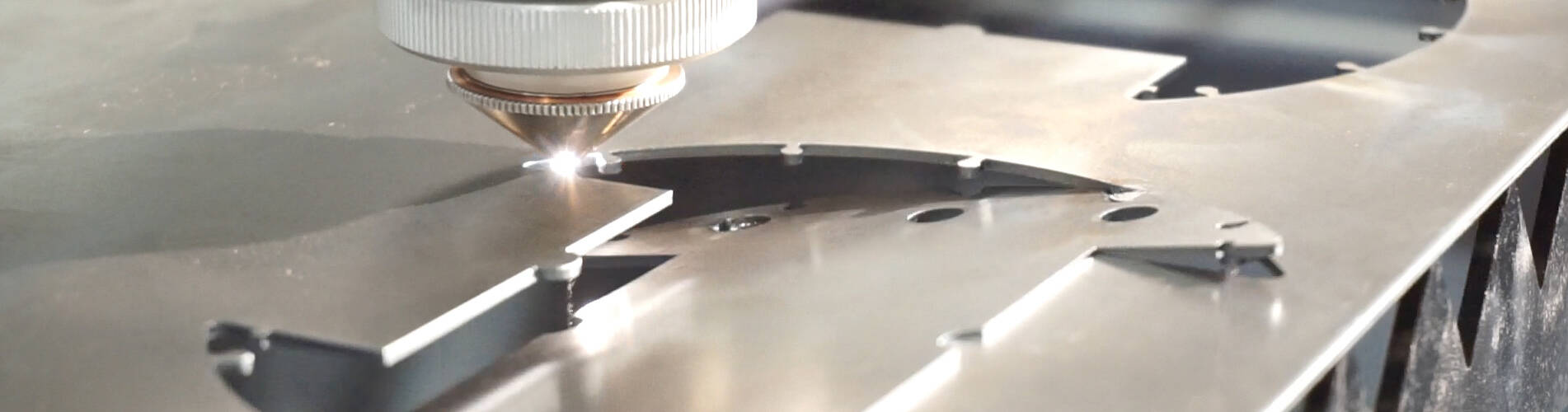

Whether you’re in need of custom parts or engraved materials, there’s no doubt that laser cutting offers the best precision for these projects. While machine tooling is an older process, this method of laser cutting is much more efficient and there’s less room for error. How do lasers cut, engrave, and mark metal/acrylic parts? Keep reading to learn a little more. Why is this method of cutting pre...

The application of CNC technology in the field of machining and manufacturing can meet the needs of modern society for product diversification and the requirements of product upgrading, and it can also promote the development of machinery manufacturing in the direction of precision, modernization, technology and intelligence. That makes the machinery manufacturing industry has achieved faster deve...

If you have ever considered stainless steel for a project, you know it’s a high-quality but costly material to manufacture with. While this material can seem expensive compared to other metals, however, the cost represents a value that no other materials can provide. Stainless steel offers numerous benefits to engineers and designers, from long-term value to range of applications. To understand th...

When you are ready to produce the products to test market, do you want to directly find the mould factory to make a mold to processing? When you receive the mould cost, you may ask why its cost is so high? When you have a general understanding of the mould manufacturing process, you probably don’t think it’s expensive. The mould manufacturing process generally includes: product analysis- mould des...

Are you looking for a more efficient and cost-effective process to cut and engrave your products or parts? Laser cutting and laser engraving service are increasing in popularity over traditional multi-station punch processing, especially in the United States. How does laser cutting work? A laser cutting machine uses a laser beam to cut materials such as acrylic, plastic, and metal. The beam is dir...

Which is the right crystal for my watch? As the window to your timepiece, the watch crystal (or “glass”) takes some of the hardest hits and is the brunt of everyday wear and tear. There are 3 main types of watch crystal: Plastic / Acrylic: These used to be the norm. The plastic material is relatively soft, so as you would expect, it is the least expensive. Because it is quite soft and flexible, it...

Laser Engraving is a well established process in heavy industry for marking and engraving tools, assets, products and many more. But it has only recently been adopted by start up business’ as a service to an end user and the general public. Laser engraving is a process which uses laser technology to engrave, cut or mark materials, using an intense beam of laser light. Traditionally, engraving was ...

1

22

pagesCategories

Recent Posts

Copyright © 2025 Shenzhen Jiamei Photoelectric Technology Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported