Are you looking for a more efficient and cost-effective process to cut and engrave your products or parts? Laser cutting and

laser engraving service are increasing in popularity over traditional multi-station punch processing, especially in the United States.

How does laser cutting work?

How does laser cutting work?

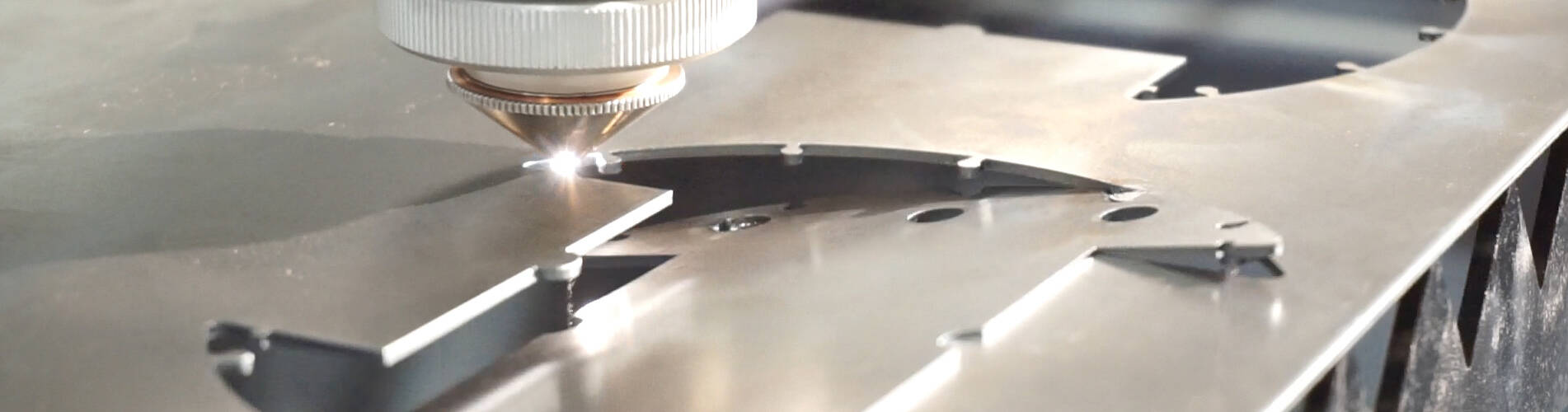

A laser cutting machine uses a laser beam to cut materials such as acrylic, plastic, and metal. The beam is directed at the surface, and it melts and evaporates the target area(s).

Why is laser cutting so popular?

1.Accuracy: Laser cutting and measuring are accurate within one nanometer. This is of critical importance for industries with tight standards or regulatory requirements such as with military, government, medical, and electronics applications.

2.Flexible cutting: A laser can cut many different types of material. The most popular is a custom laser cutting acrylic. It can also cut metal, plastic, glass, fiberboard, card stock, and fabric.

3.Flexible engraving: A laser can engrave many different types of material. These include wood, laminates, marble, stone, and acrylic.

4.Large volume support: Laser cutting is especially effective when working with large volumes or a similar product.

5.Nice for the work environment: Laser cutters have minimal vibration in the equipment and low processing noise.

It found that the most used laser technique is cutting, which surpassed both area and line engraving. The most used material for laser cutting was acrylic, by metal. The most used kind was a

custom laser cutting acrylic. Last, by a landslide, the United States was the region with the most laser cutting activity.

You have the option of buying the laser cutting equipment for your production team or you can outsource your needs to an industry expert. Outsourcing, in most cases, will save you time and money. It can also free up storage space in your warehouse. Your employees will be freed up to work on other value-added activities.

Look for a laser cutting company that has multiple lasers so they can deliver short lead times. See if they can work from a pencil sketch or a cad file to produce your designs. Ensure they can respond quickly to questions and quote requests. Consider a company that can

custom laser cutting service.

Contact a laser cutting and engraving company today and find out if lasers are right for your production line.

For more info, please visit

www.jmintek.com.

ATT: Allen Xu

Mobile: 0086 133 1646 6330

Skype: Jiamei Ltd