What is sandblasting?

Blasting is essentially like a pressure washer that uses “abrasive media” to create the desired look. The abrasive material we use includes sand, garnet, walnut shells, glass beads, and high-pressure water.

We will pick the media, the pressure, the distance from the part after taking the desired surface texture, the material of the part, and the dimensional tolerances of the finished part into considerations.

Advantages of sandblasting

Sandblasting finishing can create a uniform matte texture by shooting the media at a surface using air pressure.

The blasting process removes surface deposits and many cosmetic imperfections.

It also improves the appearance of metal surfaces and prepares surfaces for painting.

Applications of blasting

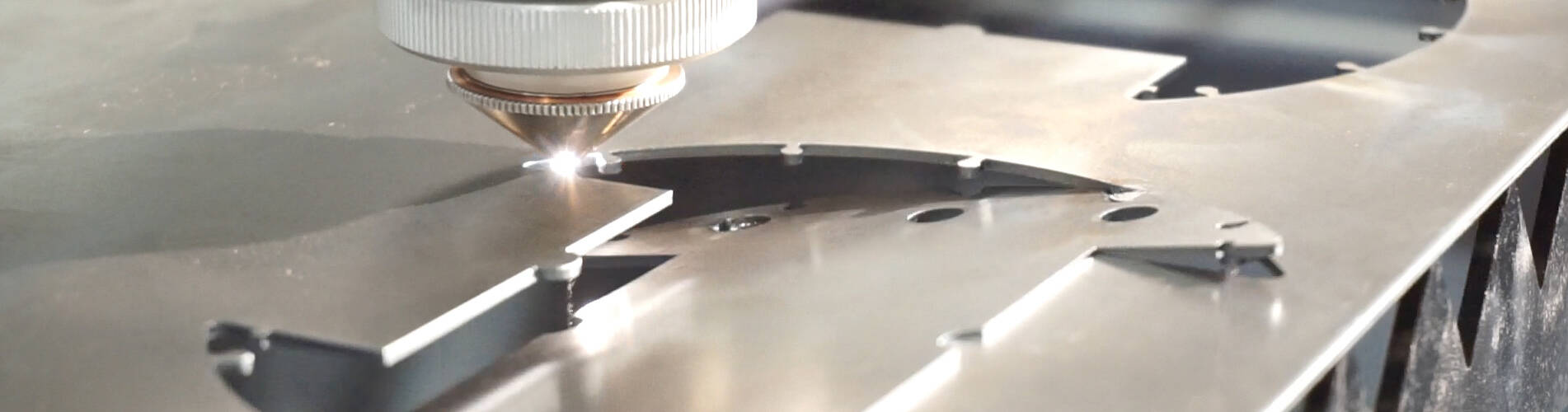

The

metal blasting process is often applied to Aluminum, Stainless Steel, Copper, Steel, Brass, Titanium and Bronze. The plastic blasting process can be applied to most of plastic parts.

Blasting is a low-cost process often used for decorative parts, you can supply your own parts or we can manufacture and blast parts for you. We’re ready to help you in short and long runs.

Advantages of anodizing

Advantages of anodizing

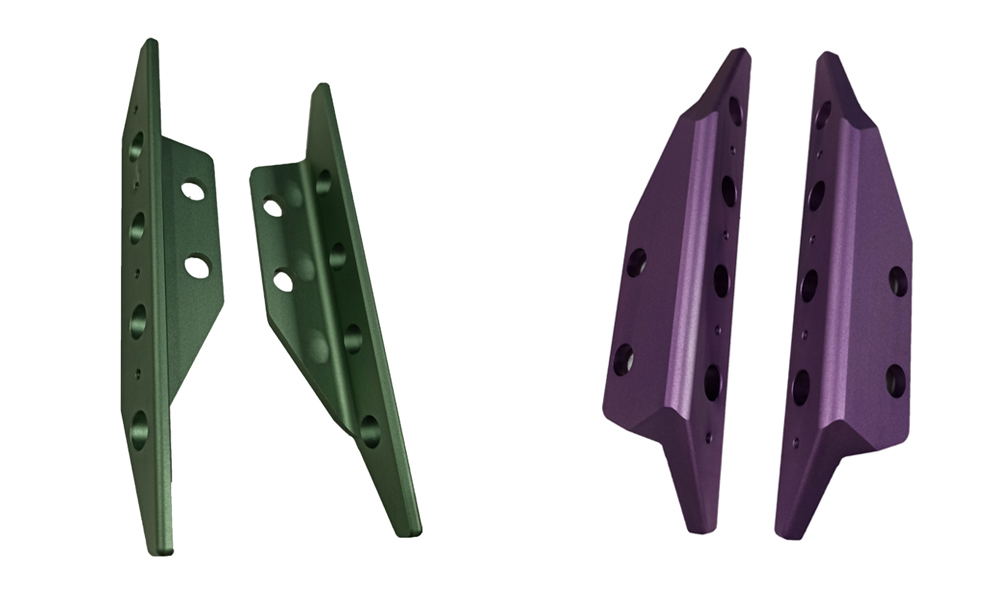

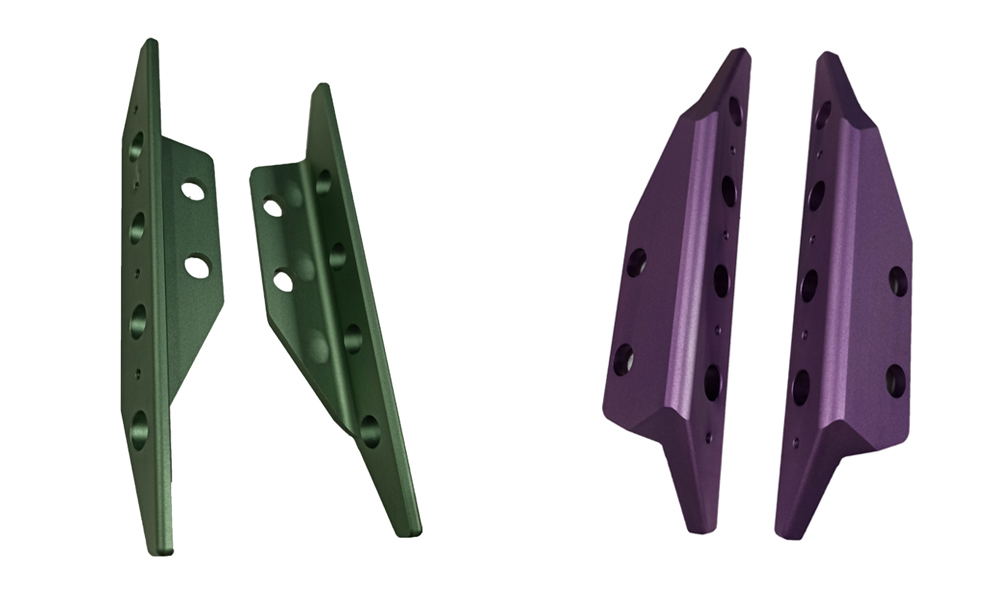

Anodizing is a finish that makes parts to be more decorative, durable, corrosion-resistant. The process is also used to offer different colors, improve surface uniformity, and increase resistance to were from normal handling and usage.

Applications of anodizing

Anodizing finishing is most commonly applied to protect aluminum alloys, but we also do it on processes magnesium and titanium parts.

Colors

Colors often required include black, blue, red, gold and non-dyed. However, we are able to offer colors match to in Pantone.

Call us today at +86 133 1646 6330 or send an email to allen.x@jmintek.com to learn more.