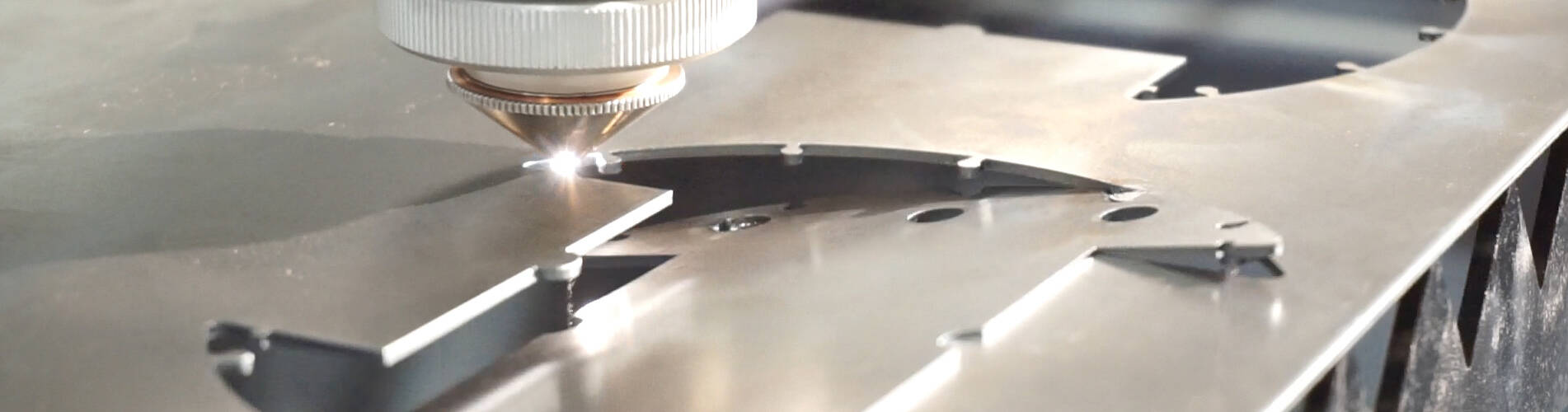

Whether you’re in need of custom parts or engraved materials, there’s no doubt that laser cutting offers the best precision for these projects. While machine tooling is an older process, this method of laser cutting is much more efficient and there’s less room for error.

How do lasers cut, engrave, and mark metal/acrylic parts? Keep reading to learn a little more.

Why is this method of cutting preferable for metal/acrylic parts?

As mentioned above, this cutting process offers more precision than any other metal/acrylic cutting method. In addition, cutting metal/acrylic parts this way is more efficient. Considering lasers won’t wear down like other cutting tools, this method also ensures that efficiency over time. And with no need to rely on machining, it is often more cost-effective than other cutting practices.

How do laser cutting, marking, and engraving differ?

While the practice as a whole may have an umbrella term, laser cutting plastic parts isn’t the only service out there. Laser marking and laser engraving plastic are just as important. Here’s a quick look into each of these laser processes.

Laser cutting – Laser machines require a laser that has been designed to cut materials like acrylic and PETG. These lasers are typically the most precise, though they’re usually not class 4 lasers, which are strong enough to start a fire. In fact, there is typically minimal surface area affected by this laser’s heat output.

Laser engraving – Engraving on plastic with lasers requires a bit of adjustment. In these cases, it’s important that the laser doesn’t cut entirely through the plastic. As such, engraving lasers need to be calibrated so they can only cut to a very specific depth.

Laser marking – Laser marking may sound similar to laser engraving, but this process doesn’t involve any removal of plastic material. Despite the lack of material being removed, this process does still change the surface appearance of a piece of plastic.

Whether you need metal/acrylic parts cut, engraved, or marked, lasers are the way to go. Not only are they more efficient, this cutting method allows for more cost-effectiveness and precision. Next time you need custom metal/acrylic parts, contact Shenzhen Jiamei Ltd.